Key Technical Specifications of Jumbo Bags (FIBC) | Essential Guide for Safe and Efficient Packaging

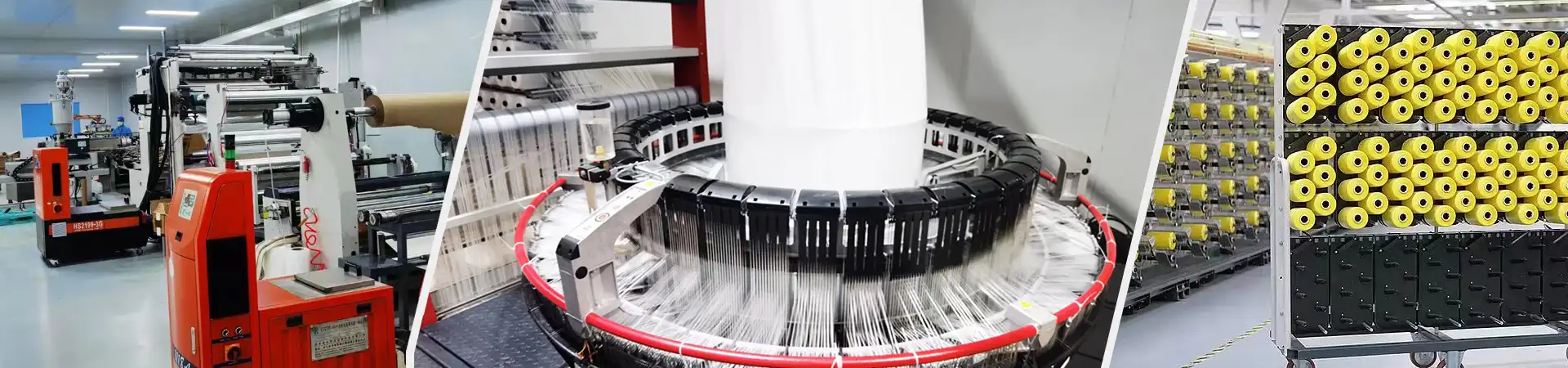

Jumbo bags, also known as FIBCs (Flexible Intermediate Bulk Containers), are widely used for the storage and transportation of bulk materials across various industries. Understanding their technical specifications is crucial for ensuring safety, durability, and efficiency.

Load Capacity & Safety Factor

-

Load Capacity: 500kg – 2000kg (customizable based on requirements).

-

Safety Factor (SF): Commonly 5:1 (single-use) or 6:1 (multi-use), ensuring durability under specified load conditions.

Material Composition

-

Fabric: Made of high-quality polypropylene (PP) woven fabric, ensuring strength and flexibility.

-

Lamination: Optional laminated or non-laminated fabric for dust-proofing and moisture resistance.

-

Lifting Loops: Reinforced loops designed for easy handling with forklifts and cranes.

Design Types

-

U-Panel, Circular, and 4-Panel Bags: Different structural designs offer varied strength and stability.

-

Top Options: Open, spout, or duffle top for different filling needs.

-

Bottom Options: Flat, spout, or discharge bottom for easy unloading.

Coating & Liner Options

-

Coated Bags: Provide additional moisture and dust protection.

-

PE Liners: Used for fine powders, chemicals, and moisture-sensitive materials.

Customization & Printing

-

Size & Strength: Fully customizable based on industry requirements.

-

Logo & Printing: High-quality printing options for branding and safety instructions.

Compliance & Certification

-

ISO, UN, SGS Certification: Ensuring quality and compliance with international standards.

-

Food-Grade Bags: Certified for safe food and pharmaceutical packaging.